|

During firmware development we needed emulation of

module function in order to prove correct operation. This page

describes the various forms of hardware we've used since the beginning

of our effort. We call these our "Stepping

Stone" hardware platforms.

Test Hardware #1 - PhyTec Board

|

PhyTec PCM-992

Our first test hardware was purchased not built. Oct 2002 when we

started the CAN-Do! firmware effort it was easier to start with the

T89C51CC01 processor on this board for some of the tests. It contained

the exact same processor so we could try out code and exercise it

without depending on working hardware in the Widget. At this time

(when we first started) we still did not know how to control the

peripherals on the Widget, so having this board allowed us to get to

working code before we had fully checked out our Widget hardware. It

gave us an alternative context in which to run the new code in order to

prove that we coded it well. The last attempt we made to use this

board was to wire it to a parallel port so we could emulate byte-pipe

traffic. This turned out to be complicated and we found ourselves

limited to uni-directional traffic over this lash-up.

Test Hardware #2 - Wire-Wrap Board

|

|

Wire-Wrap

w/Widget - Front / Back

As soon as our first batches of Widgets (100 in all) started arriving

in Colorado Springs we needed to exercise all of them and all

their capabilities. (Digital inputs, Digital Outputs, Analog Inputs,

Power On/Off control, etc.) Bdale built the "Wire Wrap" board

based on mix of concepts by John Conner, Bdale and Stephen.

Features of this board:

- A resistor network gives us a fixed set of values for each

of the analog inputs. These values are evenly spaced throughout the

analog sensor range. This makes it easy for us to see if any of the

analog channels are not working as expected.

- 10 Dip switches provides control over

- All 8 digital inputs (switch for each.)

- Enable / disable of resistive load so we can test

current sensor

- An LED provides easy visibility of switched power

output

- Two connectors for an Agilent Logic Analyzer (guess who

one of us works for ;-) are used to monitor all the digital

inputs and outputs

- Two connectors at bottom left for parallel cables so we

could drive the inputs, read the outputs from our earlier parallel-port

control software

During Widget initial testing Stephen drove the CAN bus

writing tools and flashing while Bdale drove the Logic

Analyzer and the dip switches. Bdale stimulated things and

read results. We traded off logging of our results.

Randomizing the DIP SW patterns always kept us on our toes

;-).

We tapped a Radio Shack DVM into our CAN/Power cable so we

could measure Widget current draw during the testing as

well.

schematic: TBA

developed by:

Bdale Garbee, KB0G, John Conner, NJ0C, and

Stephen Moraco, KZ0Q

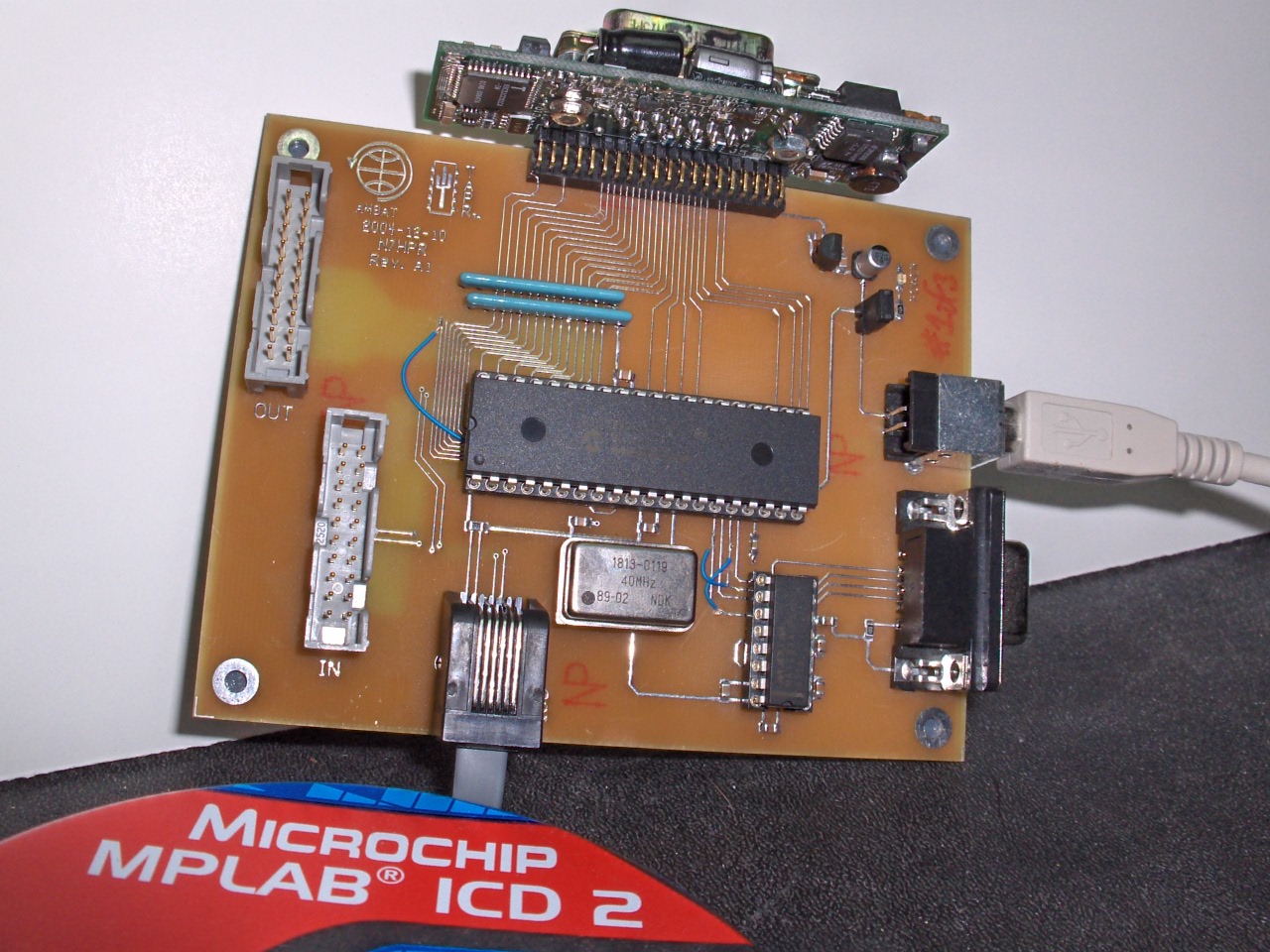

Test Hardware #3 - PIC-based Pipe-Mode Emulator

|

PIC-based

PipeMode Emulator w/Widget

As soon as we stepped into development of the pipe-mode firmware it

became clear that this could not be made to work unless we had specific

hardware. At our AMSAT annual conference in 2003 we asked for help

building such a board. Steven Bible, N7HPR volunteered to help.

We developed a specification from

which he developed and built the board. After getting enough basic

firmware working, he handed the whole thing off to Stephen (around Feb

2005) to complete the firmware and get on with developing the pipe-mode

firmware. This board worked well. We developed and released the first

working byte-pipe firmware using this test environment.

Features of this board:

- PIC-based board with onboard FLASH memory for code

- ANSI C development environment

- ICD-2 in-circuit debugger / firmware loader

- Functions controlled via serial port command interface

(communicated with running board via hyperterm windows application

- Two connectors for an Agilent Logic Analyzer are used

to monitor all the digital inputs and outputs

- Powered from Widget or from USB cable

- Socket mounted crystal allowing us to upgrade processor

speeds

Experience with the first implementation (we now have

three of these) exposed a limitation in hardware (PIC

speed). However, that was quickly addressed by replacing the

crystal and the PIC with faster versions. The great thing

about using the PIC was that we simply moved to a pin/code

compatible faster version with hardly any more work than a

re-compile of the code for the new PIC microprocessor.

This test board still serves well today when working on byte-pipe

mode testing. Our next immediate effort is to accomplish the

1st

implementation of the Pipe-mode file transfer protocol.

This board may

be a candidate for that testing.

developed by: Steven Bible,

N7HPR

from specification:

Pipe-mode Emulator Test Fixture Spec

schematics:

PIC

-based Pipe Emulator Schematic and Board Layout

Test Hardware #4 - Spartan3E Xilinx Demo Board with Widget Adapter

|

Spartan3E

w/Widget I/F Board

As I was wrapping up my first implementation of the pipe-mode

firmware for the Widget, I became concerned that we had not tested the

pipe mode function at best speed. Also, in working with the

Arizona Star Camera team, I saw a number of issues. I found that I needed to better understand what it took to build hardware to interface

to our byte-pipe mode Widget. Around the time I identified this need I

was asked to better understand Xilinx implementation of circuits for my

real work. I decided to marry these two needs by purchasing the

demo board and then designing and implementing a Widget interface for

the board. Lyle Johnson, KK7P, kindly guided me through this, my first

ever, PCB implementation.

Features of this board:

- Xilinx-Spartan3E demo board

- Xilinx tool-chain supporting VHDL/Verilog implementation

with support for embedded cores (PicoBlaze, MicroBlaze,

and PowerPC)

- Two connectors for an Agilent Logic Analyzer are used

to monitor all the digital inputs and outputs

- A single high-density Soft-touch Pro connector for a Logic

Analyzer

- Pipe handshake lines are LED-monitored, w/two extra LED

outputs for misc. use

- Many switches, push-buttons, LED, Ethernet, USB, etc.

available for use in design

Testing with this board provides confidence that the

current pipe-mode firmware can run with very fast module

implementations without negatively affecting Widget

performance. This proves that Widget firmware implementation

is robust from slow speed module implementations through to

high speed module implementations.

In the near future with this board, we will be experimenting with using

the GNU compilers for building the file-transfer module side first

implementation.

main board: purchased

Widget I/F board developed by:

Stephen Moraco, KZ0Q

specification, Schematics and

Board Layout:

Spartan3E

Widget I/F Test Fixture Spec

Example top-level Xilinx Design:

Simple pipe

auto-responder

Test Hardware - The future?

These boards each have served us well. However, if we are to

develop more Widgets then we will have to build a basic functional test

platform. Today, each time we prepare a batch of Widgets for use

or prepare them even for flight, we find ourselves running the entire

test suite by hand using the Wire Wrap board. This is time

consuming as it is an entirely manual process. Our best

improvement here would be to automate the testing and recording of

results along with contrasting the behavior of tested Widget against others

in the batch.

Now you have a feel for how involved we have been in developing

and testing the Widget firmware through 1st implementation. You

can see that we've been investigating all aspects of performance and

function. We have been using custom hardware to make this testing as

robust as we practically can.

If you have questions, suggestions or would like

further

information feel free to contact me.

- Stephen KZ0Q

|